Blog

10 Essential Tips for Effective Tank Level Monitoring System Management

In the realm of industrial processes and supply chain management, the efficiency of a tank level monitoring system is paramount for ensuring optimal operations. These systems play a critical role in maintaining the appropriate storage levels of liquids and other materials, thereby preventing overflows, shortages, and potential system failures. Effective management of a tank level monitoring system not only enhances operational efficiency but also contributes to safety and sustainability practices within various industries.

As companies seek to modernize their operations and incorporate advanced monitoring technologies, understanding the best practices for managing a tank level monitoring system becomes essential. This includes selecting the right technology, maintaining accurate readings, and implementing robust data analysis tools. By focusing on the key elements that contribute to effective tank level monitoring, organizations can significantly improve their inventory management, reduce costs, and ensure compliance with regulatory standards. In this article, we present ten essential tips to optimize the management of your tank level monitoring system, ultimately leading to a more streamlined and efficient operational framework.

Understanding Tank Level Monitoring Systems and Their Importance

Tank level monitoring systems play a crucial role in effective water management, particularly in the context of urban environments facing rapid growth and resource strain. As communities expand, often into informal settlements, the demand for reliable water usage assessments becomes paramount. Innovations in smart monitoring technologies, including digital twin applications, offer the potential to enhance these systems significantly, ensuring that water resources are utilized efficiently and sustainably.

Furthermore, recent studies have highlighted the vulnerabilities within automated tank gauge systems, raising awareness of the need for robust monitoring frameworks to prevent potential failures. Effective management of these systems not only minimizes risks associated with water scarcity and flooding but also promotes better sanitation practices, ultimately contributing to public health. Understanding the functions and importance of tank level monitoring is essential for building resilient urban water systems that can adapt to ongoing changes and challenges.

10 Essential Tips for Effective Tank Level Monitoring System Management

| Tip Number | Tip Description | Potential Benefits | Implementation Difficulty |

|---|---|---|---|

| 1 | Choose the Right Monitoring Technology | Improved accuracy in readings | Moderate |

| 2 | Regular Calibration of Sensors | Ensures reliable data | Easy |

| 3 | Set Appropriate Alarm Levels | Reduces risk of overflow or shortage | Moderate |

| 4 | Implement Remote Monitoring Solutions | Access data from anywhere | Challenging |

| 5 | Ensure Regular Maintenance | Prevents system failures | Easy |

| 6 | Train Staff on System Use | Maximizes system potential | Moderate |

| 7 | Utilize Data Analytics | Improves decision making | Challenging |

| 8 | Regularly Review Data Reports | Helps identify trends | Easy |

| 9 | Install Backup Systems | Enhances reliability | Moderate |

| 10 | Evaluate System Performance Regularly | Ensures continued efficiency | Easy |

Key Components of a Tank Level Monitoring System

A tank level monitoring system is crucial for maintaining efficiency and safety in various industries. Understanding its key components can significantly improve operational management. Typically, a system comprises sensors, controllers, and communication interfaces that work together to provide real-time data. Sensors measure the liquid levels accurately, while controllers process this data to trigger alerts and maintain desired levels.

To ensure effective management, consider implementing regular maintenance on your sensors. This helps prevent inaccuracies that could lead to overflows or shortages. Additionally, training staff on how to interpret data from the controller can enhance decision-making processes. Keeping your communication interfaces updated ensures that data is relayed efficiently, minimizing delays in response times.

Another essential aspect is integrating your tank level monitoring system with other automation systems in use. This synergy allows for better resource management and can optimize operational efficiency. By focusing on these key components and best practices, companies can streamline their processes and enhance their tank level monitoring capabilities.

Tank Level Monitoring System Data Analysis

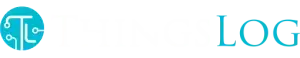

Best Practices for Installing Tank Level Sensors

When installing tank level sensors, it is crucial to choose the right type of sensor for your specific application. Various technologies, such as capacitance, ultrasonic, and radar sensors, each have their unique advantages and limitations. Take into account factors such as tank material, shape, and the nature of the liquid being monitored. Properly evaluating these elements ensures the selected sensor will provide reliable and accurate data.

Additionally, positioning the sensor correctly within the tank is vital for optimal performance. Sensors should be installed away from any disturbances, such as inlets and outlets, to minimize interference from turbulence. It’s also essential to adhere to the manufacturer’s guidelines regarding installation height and angle, as these factors can significantly impact measurement accuracy. Prioritizing these best practices during installation will enhance the functionality of your tank level monitoring system and contribute to more efficient management of resources.

Regular Maintenance Tips for Optimal Tank Monitoring Performance

Regular maintenance is crucial for ensuring the optimal performance of tank level monitoring systems. According to a report by the American Society for Quality (ASQ), regular maintenance can reduce system downtime by as much as 25%. To achieve this, operators should establish a maintenance schedule that includes routine inspections, calibration checks, and system updates. This proactive approach not only helps in identifying potential issues before they escalate but also ensures that the system operates within its optimal range, thereby maintaining accuracy in level readings.

Moreover, data from a survey conducted by the Industrial Internet Consortium (IIC) indicated that 70% of organizations that implemented systematic maintenance protocols saw a significant improvement in data accuracy and reliability in their monitoring systems. This underscores the importance of not just maintaining equipment, but also ensuring that all software components are kept up-to-date to leverage the latest functionalities and security advancements. Regular training for personnel on new technologies and methodologies also plays a vital role in enhancing the effectiveness of tank level monitoring systems, leading to better decision-making and resource management overall.

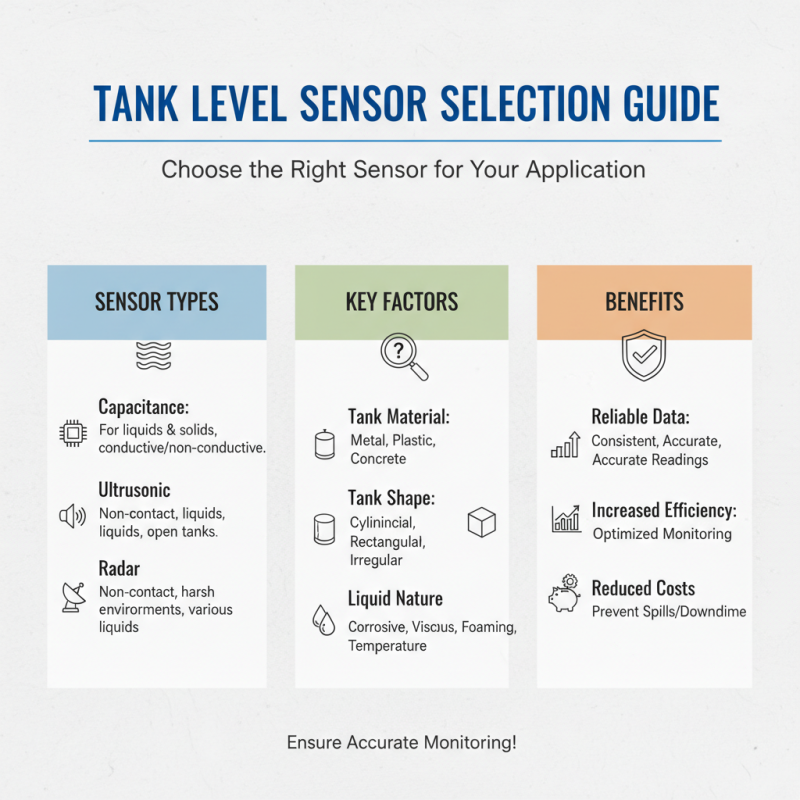

Data Analysis Techniques for Enhanced Tank Level Management

Effective tank level management is crucial for various industries, including oil and gas, chemicals, and water treatment. Implementing robust data analysis techniques not only enhances monitoring accuracy but also optimizes operational efficiency. According to a recent report by MarketsandMarkets, the global tank level monitoring market is projected to reach $2.5 billion by 2025, highlighting the growing importance of effective management systems.

To maximize the benefits of tank level monitoring, adopting advanced data analysis techniques is essential. One effective approach is employing predictive analytics, which utilizes historical data to forecast future tank levels. This allows organizations to anticipate demand and plan logistics more effectively. Another crucial tip is to integrate Internet of Things (IoT) technology, providing real-time data access and insights. A study by Frost & Sullivan indicates that IoT-enabled tank monitoring can improve supply chain efficiency by up to 25%.

Furthermore, regularly reviewing data patterns and anomalies empowers operators to make informed decisions promptly. Implementing machine learning algorithms can facilitate the identification of trends within tank levels and automate alerts for unexpected changes. This proactive approach not only prevents overflows but also reduces downtime, ensuring continuous operations and enhanced safety measures across facilities.

Related Posts

-

2025 How to Optimize Your Tank Level Monitoring System for Maximum Efficiency

-

Top 5 Data Loggers to Watch for in 2025 That Will Revolutionize Your Data Collection

-

10 Best Power Monitors to Optimize Your Energy Usage in 2023

-

2025 Top 10 Data Loggers You Can't Miss: Ultimate Buying Guide

-

Top 5 Power Monitoring Systems to Boost Energy Efficiency by 30% in 2023

-

Why You Need a Power Consumption Meter to Save Energy and Reduce Costs