Blog

How to Implement a Tank Level Monitoring System Effectively?

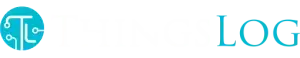

In today's industrial landscape, a reliable tank level monitoring system is crucial. These systems track fluid levels in real-time, ensuring operational efficiency. Proper implementation can prevent costly spills and enhance resource management.

However, many companies struggle with installation and maintenance. They often underestimate the complexity of integrating this technology. A few errors can lead to inaccurate readings or system failures. Regular calibration and staff training are vital. Without these, the benefits of a tank level monitoring system diminish significantly.

This guide will explore effective strategies for implementing such systems. It will address common challenges and potential pitfalls. Stakeholders must be aware of the nuances involved. A thoughtful approach can ensure that the tank level monitoring system delivers maximum value and reliability.

Understanding the Importance of Tank Level Monitoring Systems in Industry

Tank level monitoring systems are critical in various industries. They help manage resources efficiently. Understanding their importance can lead to better operational decisions. Accurate monitoring prevents overflows and shortages, ensuring seamless operations. In industries like oil, water treatment, and chemicals, these systems enhance safety and compliance.

Tips: Regular calibration of sensors is vital. This ensures accurate readings. Additionally, consider integrating alarms for low or high levels. This can minimize risks effectively. Monitoring software should be user-friendly. Complex systems can lead to errors, which can be costly.

Implementing a tank level monitoring system may seem straightforward, but challenges exist. Training staff is essential. Without proper knowledge, the system's efficiency is compromised. Maintenance is another aspect to reflect on. Neglected systems can yield inaccurate data. Over time, this can lead to operational inefficiencies and increased costs. Regular audits can identify potential issues early on.

Key Technologies Used in Effective Tank Level Monitoring Solutions

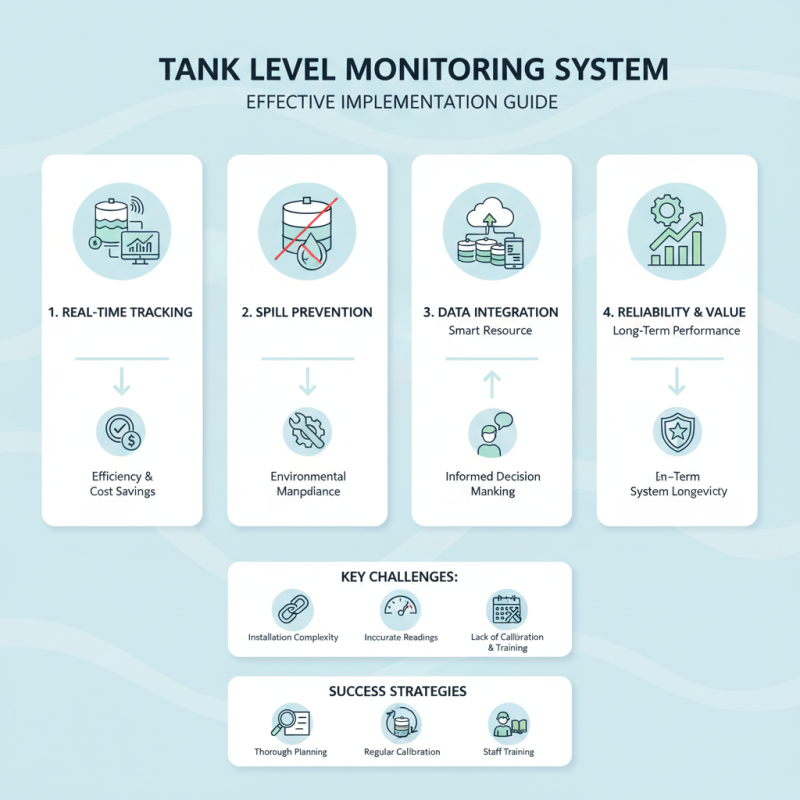

Implementing a tank level monitoring system requires key technologies that enhance accuracy and reliability. One of the most widely used technologies is ultrasonic measurement. This method employs sound waves to detect the liquid level. It is simple and cost-effective, but it can be impacted by temperature changes and vapors. Regular calibration is necessary to maintain precision.

Another technology involves capacitive sensing. This approach measures changes in electrical capacitance as a tank fills or empties. It works well for various liquid types, including non-conductive fluids. However, there are limitations. For instance, the sensor may require cleaning to prevent false readings. The installation process can also be intricate, leading to potential user errors.

Radar-based sensors are gaining traction in modern systems. They offer high accuracy and work well in challenging environments, such as high-pressure tanks. Still, they can be expensive and require careful setup. Additionally, environmental factors might interfere with their signals, causing fluctuations. This aspect highlights the need for thorough testing to ensure reliability over time. Each technology presents unique challenges and benefits, making it essential to choose wisely based on specific needs.

Steps to Configure Sensors for Accurate Level Measurements

When configuring sensors for a tank level monitoring system, accuracy is key. Begin by selecting the right type of sensor based on the tank's dimensions and the liquid being monitored. Ultrasonic sensors are often a good choice for non-contact measurement. However, they can struggle with foamy surfaces or extreme temperatures. Testing your sensor in different conditions can reveal its limitations.

Once the sensor is chosen, proper installation is crucial. Ensure that sensors are mounted at the correct height. Misplacement can lead to inaccurate readings. Pay attention to obstacles that may interfere with sensor signals. This includes ladders, pipes, or other equipment in the area. Review the setup frequently, and be open to adjustments based on performance data. Regular calibration is essential to maintain precision over time, and failure to do so may result in significant errors.

Data processing is another area requiring careful consideration. It’s important to select the right algorithms for interpreting the sensor data. Simple averaging might not be enough in turbulent conditions. Testing different methods is advisable. Be prepared to revise your approach and embrace mistakes as learning opportunities. Proper configuration, meticulous attention to detail, and a willingness to adapt will lead to more reliable tank level monitoring.

Data Management and Visualization Best Practices for Monitoring Systems

Effective data management is crucial in tank level monitoring systems. Accurate data collection relies on reliable sensors and regular maintenance checks. According to a report by the American Petroleum Institute, nearly 35% of leaks in tanks occur due to poor monitoring practices. This highlights the need for consistent data accuracy.

Visualization plays a significant role too. Real-time dashboards can help operators make informed decisions quickly. Research from the International Journal of Industrial Engineering shows that clear visual data representation reduces response time by 30%. Integrating advanced analytics can further enhance understanding, but data complexity can also become an obstacle. Too many data points can overwhelm users, potentially leading to errors.

Users need to balance detail with clarity. It’s tempting to display all available data. However, a focus on key metrics may improve decision-making. Continuous feedback from users is essential. Regularly reassessing the effectiveness of visualization tools can reveal areas needing improvement. Monitoring systems are evolving, but ongoing reflection on data practices is vital for success.

Tank Level Monitoring: Daily Water Levels

Implementing Alarms and Alerts to Enhance Operational Safety

Implementing alarms and alerts in a tank level monitoring system is crucial for enhancing operational safety. A well-designed alert system can reduce risks. According to industry reports, nearly 30% of workplace accidents occur due to improper levels of hazardous materials. Timely alerts can prevent spills or overflows which result in costly damage and safety concerns.

Effective alarm systems must be customizable. Each facility has unique requirements. Monitoring parameters might include tank temperature, pressure, and liquid levels. Alerts should be visual and auditory to capture immediate attention. Real-time data is essential; delays could worsen situations. A report states that over 40% of accidents stem from delayed responses to warnings.

Challenges exist when implementing these systems. Employees may become desensitized to frequent alarms. Therefore, regular training is necessary to emphasize the importance of alerts. Identifying false alarms is also important. This requires constant refinement of alert thresholds. Ignoring these aspects may lead to potential risks and ineffective responses during critical situations.

Related Posts

-

Top Benefits of Tank Level Monitoring Systems for Efficient Operations in 2025

-

Best Digital Water Meters for Accurate Consumption Tracking and Easy Monitoring

-

How to Choose the Best Power Monitoring System for Your Needs in 2025

-

Top 2025 Power Monitoring Systems: How to Choose the Right One for Your Needs

-

Top 10 Benefits of Using LoRaWAN Sensors for Smart Cities and Agriculture

-

10 Essential Tips for Effective Tank Level Monitoring System Management