Blog

2025 How to Optimize Your Tank Level Monitoring System for Maximum Efficiency

In the ever-evolving landscape of industrial operations, the efficiency of a tank level monitoring system has never been more crucial. Experts emphasize that optimizing these systems can lead to significant improvements in resource management and operational productivity. As noted by industry leader Dr. Jane Thompson, renowned for her insights in process automation, "A well-tuned tank level monitoring system not only reduces waste but also enhances overall operational efficiency." This highlights the importance of integrating advanced technologies and practices in tank level monitoring to ensure maximum performance.

In 2025, businesses face increasing pressures to optimize their processes while minimizing costs. Implementing state-of-the-art tank level monitoring systems can provide real-time data and analytics, allowing for better decision-making and resource allocation. The effectiveness of these systems lies not only in their technology but also in their adaptability to different operational needs. As industries strive for efficiency, understanding how to enhance tank level monitoring systems will be critical for sustaining competitive advantage. By focusing on innovative approaches and best practices, organizations can ensure they are equipped to meet future challenges head-on.

Maximizing Tank Level Accuracy: Key Technologies for Monitoring Systems in 2025

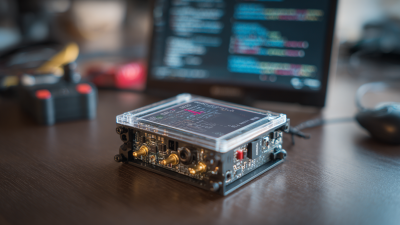

In 2025, ensuring accurate tank level monitoring is crucial for operational efficiency across various industries. One of the key technologies driving precision in this area is the use of advanced ultrasonic sensors. These sensors provide real-time data on liquid levels without making contact with the substances, minimizing the risk of contamination and improving safety. Additionally, integrating IoT connectivity allows for remote monitoring and analysis, enabling operators to make informed decisions based on up-to-date information.

Another significant technology is radar level measurement, which operates effectively regardless of temperature and pressure variations. This method uses microwave signals to determine level changes, providing reliable readings even in challenging environments. Coupled with machine learning algorithms, these systems can predict usage patterns and alert personnel to potential issues before they escalate, further enhancing operational efficiency. By investing in these technologies, companies can optimize their tank level monitoring systems, ultimately resulting in cost savings and increased productivity.

2025 How to Optimize Your Tank Level Monitoring System for Maximum Efficiency

| Technology | Accuracy (%) | Response Time (seconds) | Installation Cost ($) | Maintenance Frequency (months) |

|---|---|---|---|---|

| Ultrasonic Sensors | 98 | 1 | 250 | 12 |

| Capacitance Level Sensors | 95 | 0.5 | 300 | 6 |

| Radar Level Sensors | 99 | 0.2 | 800 | 18 |

| Optical Level Sensors | 97 | 0.8 | 200 | 9 |

| Hydrostatic Pressure Sensors | 96 | 0.6 | 400 | 12 |

Integrating IoT Solutions: Enhancing Real-Time Data Collection and Analysis for Tanks

The integration of IoT solutions in tank level monitoring systems is poised to transform the efficiency and effectiveness of real-time data collection and analysis. By leveraging advanced technologies, businesses can enhance their operational capacity, ensuring seamless monitoring of water storage and management systems. With the global artificial intelligence market projected to surge from $35.65 billion in 2023 to $253.86 billion by 2030 at a staggering CAGR of 32.4%, the investments in IoT will undoubtedly reflect similar upward trends. This growth is indicative of a robust demand for smarter, more efficient monitoring systems that can adapt to the dynamic needs of various industries.

As the wireless tank market continues to evolve, predictions show its expansion from a valuation of $12 million in 2022 to $25 million by 2030, reflecting a CAGR of 10.3% from 2024 to 2030. This uptrend highlights the increasing adoption of wireless technologies that facilitate remote monitoring, thus reducing the need for manual procedures and minimizing operational risks. Additionally, the level sensor market is also experiencing significant growth, driven by innovations that utilize contact and non-contact technologies, such as ultrasonic and radar systems. These trends underscore the critical role of IoT in optimizing tank level monitoring systems, ultimately leading to enhanced efficiency and operational resilience.

Utilizing Predictive Analytics: Reducing Downtime and Maintenance Costs in Tank Management

Predictive analytics is revolutionizing tank management by enabling organizations to monitor tank levels and conditions with unprecedented accuracy. By leveraging historical data and advanced algorithms, companies can anticipate when tanks will reach critical levels, thereby significantly reducing the risk of unexpected downtime. This proactive approach allows for timely interventions, ensuring that operations run smoothly without the interruptions often associated with reactive maintenance.

Incorporating predictive analytics into tank level monitoring systems also translates to substantial cost savings. By identifying potential issues before they escalate, companies can minimize maintenance expenses and avoid costly repairs. Moreover, optimized inventory management results from accurate forecasting, allowing businesses to maintain appropriate stock levels and reduce waste. As a result, organizations not only enhance operational efficiency but also bolster their bottom line, creating a win-win scenario in tank management practices.

Improving Energy Efficiency: How Advanced Monitoring Can Lower Operational Costs in 2025

In 2025, the optimization of tank level monitoring systems is set to play a critical role in enhancing energy efficiency across various industries. By integrating advanced monitoring solutions, organizations can effectively track and manage their tank levels, minimizing waste and reducing the need for excess energy consumption. This proactive approach not only lowers operational costs but also contributes to more sustainable practices within the supply chain.

The global market for building automation systems is projected to experience substantial growth, driven by the demand for improved energy efficiency. With an expected size of $87.85 billion in 2025, rising to $154.74 billion by 2032, the impetus for implementing AI-driven predictive maintenance and monitoring systems becomes clear. As industries aim to leverage cutting-edge technology to streamline operations, investing in such advanced monitoring solutions can yield significant cost savings while promoting eco-friendly practices. By prioritizing efficiency, businesses can navigate the challenges of operational management more effectively in the coming years.

Implementing Regulatory Compliance: Ensuring Environmental Standards with Efficient Monitoring Systems

Implementing regulatory compliance in tank level monitoring systems is crucial for meeting environmental standards and ensuring safe operations. Efficient monitoring systems can help operators track tank levels and detect any potential leaks or spills promptly. By leveraging advanced technologies, such as IoT sensors and real-time data analytics, companies can gain better insights into their tank status and automate alerts for any deviations from regulatory requirements.

In addition to detecting irregularities, these monitoring systems can support regulatory audits by maintaining detailed logs of tank levels and operations. This data can be invaluable during inspections, showing compliance with environmental laws and helping organizations avoid hefty fines. Furthermore, integrating these systems with broader environmental management practices can lead to a proactive approach in identifying risks and implementing corrective measures, ultimately fostering a culture of compliance and sustainability.

2025 Tank Level Monitoring System Efficiency

This chart illustrates the monthly efficiency of tank level monitoring systems over the year 2025, showcasing the compliance with environmental standards.